Sweetwater Sound Project

- Coordinated Delivery

- Fabrication

- Virtual Design & Construction

- Compressed Construction Schedule

- Confined Space Installation

- Corrosion Resistance

- Design Flexibility

- Ease of Installation

Sweetwater Sound, Inc. began in 1979 as a recording studio in a Volkswagen bus. It has since become the largest online retailer of musical instruments and professional audio equipment in the United States. In 2019, the company began constructing a new 500,000-square-foot warehouse to expand its Fort Wayne, IN, campus.

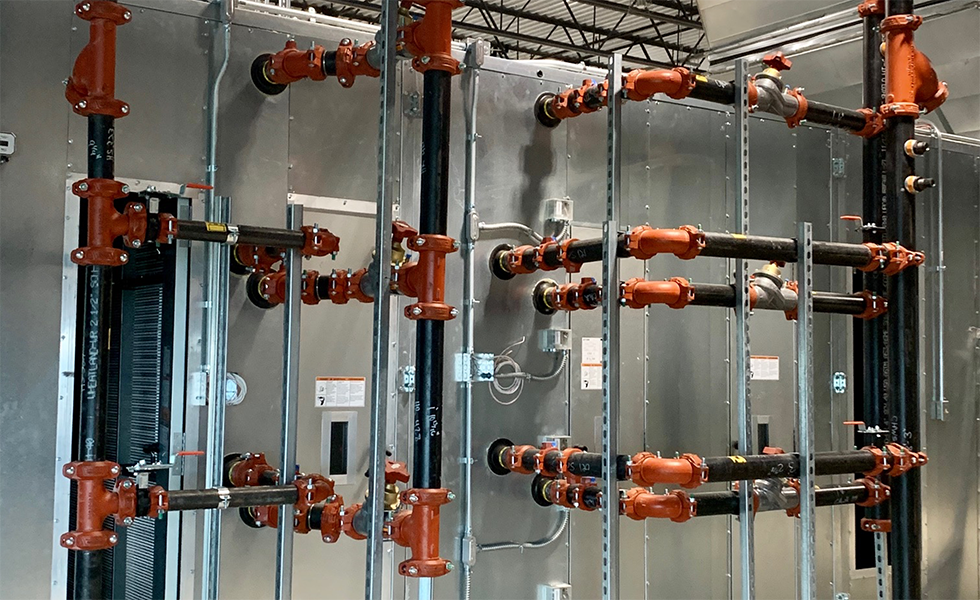

The project’s mechanical scope, contracted by Fort Wayne-based Current Mechanical, required six air handling units (AHUs) with humidification; two chillers; a two-cell cooling tower; three boilers; heating, chilled and condenser water pumps; an air piping system for conveyor systems; a domestic water system; and a reverse osmosis system for humidification. Current Mechanical has a long history of partnering with Victaulic on sophisticated projects and knew they would be the ideal partner to expedite and simplify installation for its limited crew. Specifically, they worked with the Victaulic Virtual Design and Construction (VDC) team for drawing services and fabrication schedules to maximize Current’s fabrication shop. The VDC team created 3D models of the mechanical room and complete installation drawings, which helped Current Mechanical identify and address potential issues early on to avoid costly rework. The VDC team also provided solutions for spatial challenges that arose throughout the project.

After adjusting to meet last-minute engineering design changes, Current Mechanical seamlessly began the fabrication process, which included spooling, fabrication maps, cutting lists, truck loading logs and material procurement. Victaulic provided on-site support and allocated materials ahead of time, allowing workers to save time and release materials as needed for each phase of construction. In order to accommodate the warehouse size and future expansions, this project incorporated four large AHUs that required tri-connection coils. The series of Victaulic single-coil AHU drops sped up efficiency due to their ease of installation and were installed in only four days. The compressed air system that powers the conveyors that transport instruments throughout the warehouse uses Victaulic’s QuickVic™SD Installation-Ready™System for small-diameter pipes with a thermally diffused zinc coating for improved corrosion resistance.

Victaulic products and solutions provided Current Mechanical’s team with the design flexibility and installation efficiency they needed to deliver a successful project within its nine-month timeline. Sweetwater Sound unveiled its new warehouse in 2020, with infrastructure in place to accommodate future renovations.

External Links:

Expansion Completed On Time Thanks to Effective Collaboration, Victaulic