Green Mountain DC-1 Stavanger

- Carbon Steel

- Compressed Construction Schedule

- Confined Space Installation

- Reliability

During the Cold War, the North Atlantic Treaty Organization (NATO) maintained an ammunition storage facility located deep in the mountains of Stavanger, Norway. Green Mountain purchased the space in 2009 with a vision to establish a highly secure and energy-efficient data center. Green Mountain needed to overcome installation challenges to open their one-of-a-kind data center, but trusted that the investment would be worthwhile in the end.

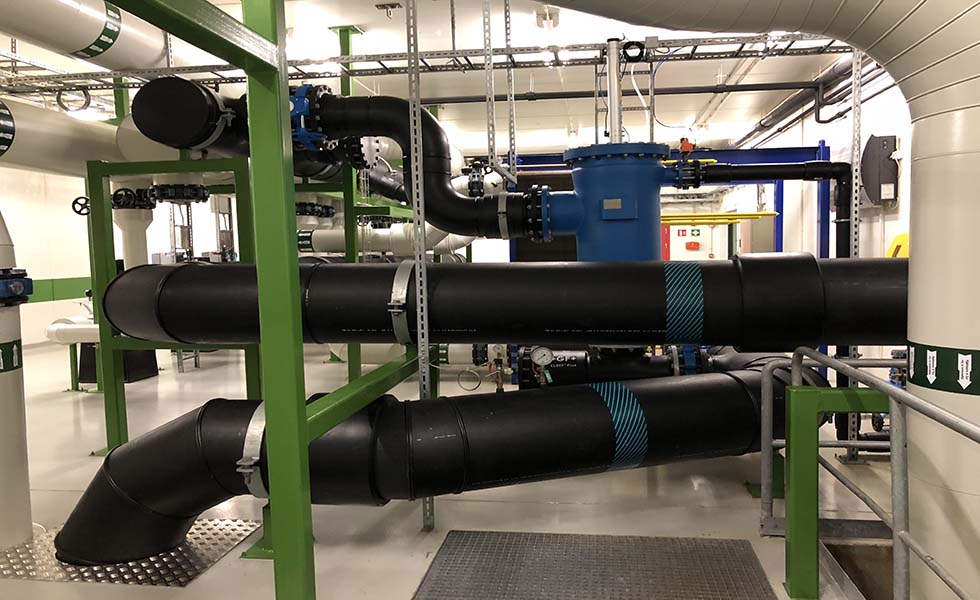

DC1-Stavanger’s pipes carry water pulled from an adjacent deep-water fjord to feed the cooling system. Overheating in data centers can result in complete shutdowns and lead to loss of data or equipment, which is why investing in a reliable and easy-to-maintain cooling system was a high priority to owners. However, the existing cooling system was located in a confined underfloor space, which created issues for both installation and maintenance. Green Mountain and Sig Halvorsen, the contractor, concluded that Victaulic’s grooved couplings, fittings, and valves provided a reliable solution that was both sustainable and scalable for the project.

The easy-to-install grooved system paired with the ability to visually confirm proper installation gave Sig Halvorsen and Green Mountain confidence the pipes were installed both quickly and correctly. Victaulic’s mechanical pipe-joining technology also granted Green Mountain flexibility to build in phases as the business expanded over time. “Using a system that is not welded provided us with the flexibility we needed and was a huge cost saver since it allowed us to build in phases. We didn’t have to make assumptions on where future data racks were going to be placed and where the cooling system should run; we were simply able to build as we grew and added customers.”

As a company operating data centers powered by 100% renewable energy, Green Mountain was pleased to partner with a fellow company committed to sustainability. Victaulic products are manufactured using 90% recycled materials. The solution also eliminated the use of welding, which releases hot fumes and gases that are dangerous for people and damaging to the environment.

The use of Victaulic’s grooved solutions helped Green Mountain and Sig Halvorsen overcome spatial, schedule, worker safety, and environmental concerns on a uniquely located project. Today, Green Mountain’s DC1-Stavanger is a world-renowned, high-security data center fueled by hydropower that can be scaled up or down depending on client needs.

External Link

Connecting One of the World’s Greenest Data Centers, Mission Critical