Big Bend Fish Return System

- FRP

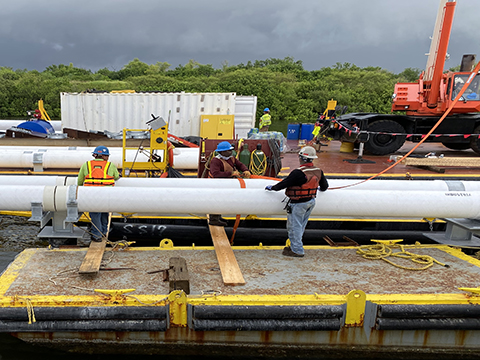

When a coal generating power plant with four coal-fired units needed a solution for a fish return system, they turned to Victaulic for accommodating pipeline movement and system reliability.

To support the cooling system at the facility, large amounts of water are pulled from a local bay. Knowing that billions of fish and wildlife are injured each year as a result of power plant cooling water systems, the facility chose to install a fish return system to reduce the environmental impact. This system safely returns the fish and wildlife to the bay.

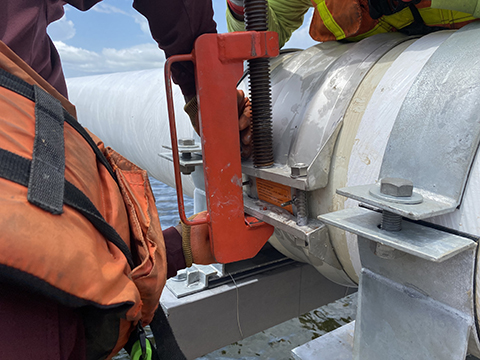

The fish return system is made up of an 18” fiberglass reinforced pipe (FRP). Victaulic Style 229S Non-Restrained Flexible Couplings for FRP were utilized throughout this system, allowing the contractor to safely join the FRP pipe. Many times, contractors are forced to join FRP pipe through “wrapping.” This pipe joining method can be potentially dangerous, costly, and require a specifically trained installation team. By using the Style 229S, the safety conditions in the field were significantly improved and the installation time was dramatically reduced.

The Victaulic Style 229S was also selected for its ability to accommodate the system’s thermal movement. Located on the coast, the power plant is exposed to extreme temperature swings that cause pipelines to expand and contract. The Style 229S Non-Restrained Flexible Couplings provided flexible capabilities that accommodate for the movement.

Along with the accommodation of thermal movement, the facility wanted the ability to easily access the fish return system for cleanouts and maintenance. Selecting the Victaulic Style 229S Non-Restrained Flexible Couplings has allowed the team to easily access their system when cleanouts or maintenance are needed. The Victaulic pipe joints can be easily taken apart and put back together by the maintenance staff, a task that would be labor-intensive and time-consuming with a butt and wrap method fiberglass joint.