ASHRAE Headquarters Project

- Project Modeling

- Virtual Design & Construction

- Compressed Construction Schedule

- Confined Space Installation

The American Society of Heating, Refrigerating and Air-Conditioning Engineers, ASHRAE, with over 50,000 members in more than 130 countries worldwide, began the construction of their 66,700-square-foot | 6,200-square-meter high-performance, net-zero headquarters in Peachtree Corners, Georgia, showcasing the latest HVAC&R equipment and technology in a built environment.

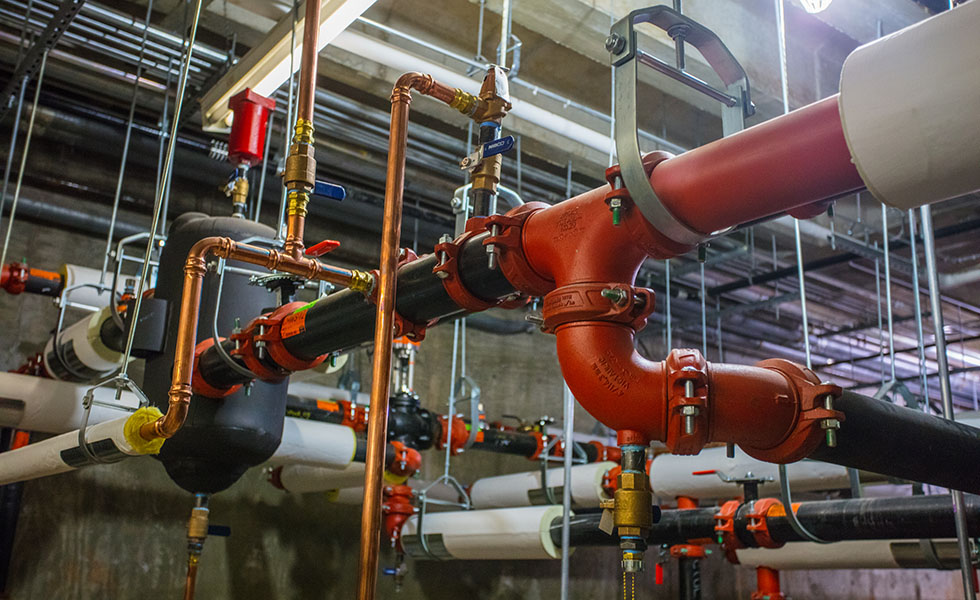

Shumate Mechanical, an Atlanta-based commercial HVAC services contractor, partnered with Victaulic to design, fabricate and install the building’s basement-level mechanical room. However this project posed a challenge: completing the facility under a compressed timeline during the onset of the COVID-19 pandemic and delivering an energy-efficient HVAC piping system. The mechanical room had limited space to fit a three-loop distribution piping system, and the timeline was compressed further due to material delays caused by the pandemic.

The Victaulic Virtual Design and Construction (VDC) team worked with Shumate Mechanical to design the mechanical room, and utilized Victaulic Tools for Revit® (VTFR) to create models with a tolerance of 1/16 of an inch (1.6 mm). First, creating a shared collaborative space for the two design teams to work in tandem was essential to completing the design. Next, capitalizing on BIM methodologies streamlined the pre-construction process and enabled complete system designs in less than three weeks.

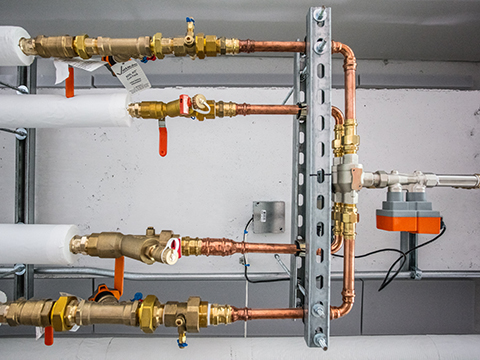

Once materials and Victaulic products arrived on site, the Shumate crew installed the HVAC system in four days. By utilizing Victaulic Vibration Isolation Pump Drops (VIPDs), outlet fittings, isolation and control valves, KOIL-KITTM coil packs, strainers and couplings gave the contracting team the confidence to complete the project both efficiently and safely. According to Doug Weaver, Division Commercial Sales Engineer at Shumate, the project also included a six-way control valve concept, unique to the radiant panel design, specifically created for the ASHRAE mechanical room. This valve concept, up-front work on the project, and Victaulic’s KOIL-KITTM coil pack parts all helped significantly speed up the construction process.

“The level of detail Victaulic provided from design through construction was noticed by everyone on the team, including the on-site foreman,” said Weaver. “It was exponentially faster to use Victaulic’s fabrication package and grooved couplings throughout the mechanical room compared to other traditional methods.”

The net-zero new-build ASHRAE headquarters was a complex project that demanded efficiency and safety. The partnership and collaboration between Shumate and Victaulic led to a successful outcome, with efficient piping installation and timely project completion.

Internal Links:

ASHRAE Installs HVAC System for New Sustainable HQ, Victaulic

External Links:

ASHRAE Installs HVAC System for New Sustainable HQ, ASHRAE Journal