200,000 Sq. Ft. Warehouse

- Cost and Schedule Certainty

- Design Flexibility

- Ease of Installation

- Improved Safety

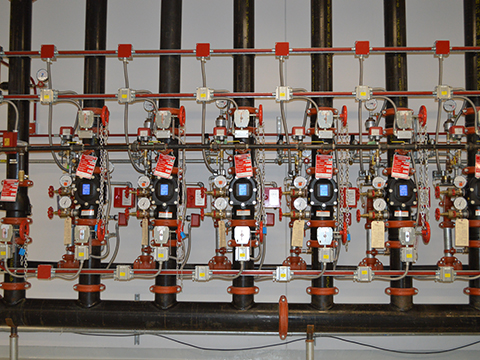

When Summit Fire Protection set out to install 2,250 fire sprinklers in a 200,000-square-feet warehouse in Ankeny, Iowa, Victaulic was ready to demonstrate how its Firelock™ IGS Style V9 sprinkler coupling and V4702 Grooved SI 24.25 (K16.8) might impact the scope of work. The fire sprinkler installer discovered an easy-to-install UL-listed and FM-approved technology that reduced total installed cost, improved fitter safety on-site and produced zero leaks across the system.

Instead of the time-consuming taping and doping end-preparation process of threaded sprinklers, the FireLock ™ IGS ™ Installation-Ready™ sprinklers enabled fitters to go directly from box to branch line and a visual inspection at every head. The solution also eliminated the use of sprinkler wrenches, which are physically demanding on workers and potentially damaging to the sprinkler frame due to the applied torque. In the end, Summit Fire Protection completed work two weeks ahead of schedule with no rework needed due to leaks.

The performance and adaptability of Victaulic’s sprinklers and couplings were important to Summit Fire Protection. As the storage demands of the warehouse fluctuate, the system can be easily dismantled, upgraded and reconfigured. Summit Fire Protection’s success using Victaulic’s grooved solutions in the 200,000-square-feet Ankeny warehouse led the fire sprinkler installer to incorporate the solution again on two other local warehouses totaling 1.6 million square feet.

External Links: