Posted on April 15th, 2024

In 1941 the United States government launched the Emergency Ship-building Program to aid the sudden need for supplies during World War II. This initiative resulted in the construction of almost 6,000 cargo ships for the U.S. Maritime Commission, roughly half of which were known as Liberty ships due to their design. Liberty ships were a vital resource during the war and carried two-thirds of all cargo that was shipped from the United States.

Because Liberty ships needed to be constructed quickly, speed and ease of system installation were the most important factors. The S.S. John W. Brown was one of the many vessels that made 13 voyages during and after the war. While these ships had an average shelf life of five years, the John W. Brown is one of two remaining Liberty ships that remains operational to this day. The reliability of Victaulic grooved couplings aided in John W. Brown’s longevity.

The advantage of utilizing grooved couplings

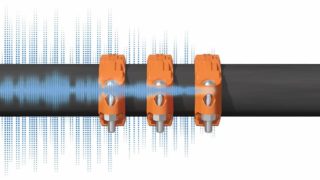

Placed in service in 1942, the Victaulic grooved pipe couplings, visible on the ship’s piping today, are the originals installed on the ballast lines.

The longevity of the John W. Brown demonstrates the advantages grooved piping systems can bring to the construction and MEP industry. Many of the qualities considered in pipe joining systems 80+ years ago remain unchanged: speed and ease of installation and maintenance, safety, reduced fire hazards and issues associated with welding, reduced downtime, and reduction in vibration and noise transmission. The Brown has proven that a well-maintained vessel with durable, reliable piping systems can greatly exceed expectations.