Posted on January 9, 2019

Improving Corrosion Resistance of Threading

Since a fire protection system’s primary purpose is to save lives and property, it is important to design the system for reliable performance. To ensure fire protection systems are operating as designed, it’s critical to keep the corrosion resistance of pipe in mind. Engineers use the Corrosion Resistance Ratio (CRR) as a measurement to determine how pipe withstands corrosion by assessing the relationship between pipe wall thickness and corrosion susceptibility. Corroded pipe can lead to perforations causing costly leaks, failure of a system and in a worst-case scenario, system failure can put individuals in harms way.

Corrosion is a massive problem when threading pipe. While it’s possible to drain systems of water, there will always be a miniscule amount present, even in dry systems. When fire protection systems are in use, oxygen will also always be present in pipe in the form of compressed air. It is inevitable corrosion will take place – with the mix of metal, water and oxygen – it creates the perfect storm for it.

A common practice is to increase the schedule of the pipe in a system to increase corrosion resistance for this pipe joining method, but this can greatly increase the cost of materials and installation. Although threading is an established method – there’s a way to increase corrosion resistance that also saves money and mitigates risk of system failure: switching to roll grooving and mechanical connections.

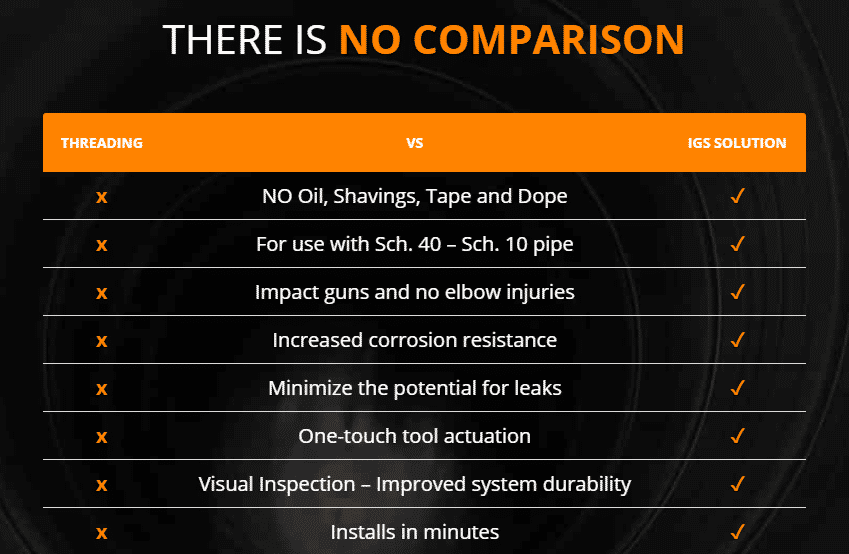

The Innovative Groove System™ | IGS replaces threaded connections with mechanical joints. IGS improves hydraulic performance and CRR while utilizing a Schedule 10 pipe, improving system durability with mechanical joints and creating a longer life span than threaded pipe.

Three reasons to switch to roll grooving instead of threading in a fire protection system

-

More Reliable Approach to Safety

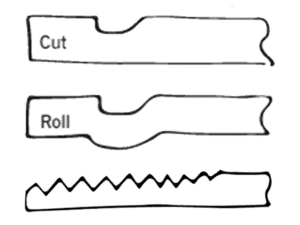

Roll grooving is a more reliable solution for small diameter 1-inch hard pipe. Contrary to cut grooving and threading, it removes no metal, so the pipe wall thickness is not compromised. Roll grooving small-diameter 1-inch pipe allows for the simplicity of using Sch. 10 pipe on an entire system while still increasing the CRR.

Pipe joining methods directly increase corrosion resistance:

- Schedule 40 equals Threaded: 1.00

- Schedule 40 equals Roll Grooved: 18.5

- Schedule 10 equals Roll Grooved: 10.1

- Schedule 5 equals Roll Grooved: 2.17

-

Innovation and Reduced Costs

The ability to use roll grooved Sch. 10 pipe instead of threaded Sch. 40 pipe on small diameter 1-inch hard pipe dramatically reduces material and handling costs and increases corrosion resistance. Benefits include:

- Improving system hydraulics by increasing the inside diameter of the pipe

- Simplifying ordering

- Ease of installation and labor

The weight difference is substantial. A suppression system constructed with grooved 1-inch Sch. 10 pipe could be as much as 17 percent lighter than a system constructed with Sch. 40 pipe, which not only makes installation easier, but considerably reduces material costs and increases corrosion resistance.

-

Compressed Project Schedules

Increase corrosion resistance by switching the pipe joining method to mechanical connections and experience the speed of the Victaulic RG2100 roll grooving tool. With up to 55 percent less pipe preparation in comparison to threading, project schedules are quantifiably condensed. Currently accepted and utilized in pipe sized above 1-inch due to the ease of installation, mechanical connections just make sense in small diameter pipe. The same reliability, ease of installation confidence Victaulic customers have come to expect from their grooved solutions, is commercially available for small diameter 1-inch pipe. Creating a fast and mess-free solution, providing repeatable, consistent grooves in under four seconds to increase corrosion resistance.

Reap the benefits of Victaulic’s award-winning FireLock™ IGS for small diameter hard-pipe solutions.