Posted on July 23rd, 2023

There is no one-size-fits-all when it comes to fire protection. Customers need reassurance that their employees, property and products are protected irrespective of their distinct fire hazards. As the built environment continues to evolve and space becomes more limited, greater innovations are needed to ensure these unique challenges are met.

Recently, Victaulic has been working closely with a forward-thinking customer to create a world fire safety class product for a unique environment. By using a relatively new to UK market product, Victaulic was able to help the customer navigate a challenging set of restrictions and ensure peace of mind regarding fire safety.

Pre-action protection

Any workplace must take special care when it comes to fire safety, but fire safety for an electrical manufacturing facility poses a unique set of challenges and risks which, left unaddressed, can be especially devastating. The electrics in question were particularly sensitive to water, which just happens to be the key component of any fire protection system. Our customer was adamant on one thing: there could be no water above the manufacturing facility. Presented with this sizeable challenge, work began on employing some inventive thinking.

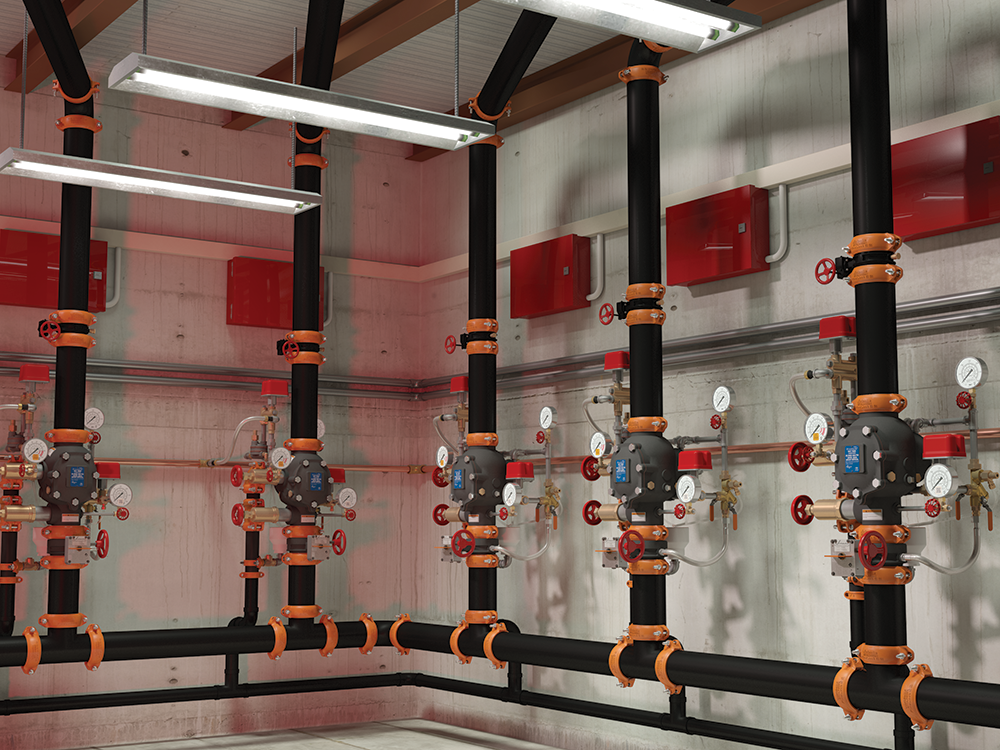

In this case a pre-action system proved to be the perfect solution, and we looked to Victaulic’s 300psi rated FireLock NXT™ Series 769 pre-action valve for execution. Considering the delicate and electrical nature of the production line, holding back the water to only be released once the system had been triggered was an integral element of the fire protection system.

A pre-action system also incorporates a double knock system, essentially requiring two different alerts before water would be released to the piping. So, if one sprinkler was knocked by accident, the whole system wouldn’t immediately kick into action as another knock would be necessary. Again, this was all with the intention of protecting the machinery from unnecessary water damage unless it was strictly necessary.

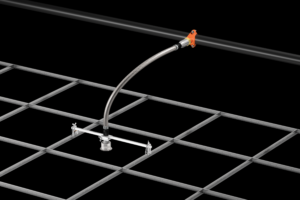

Another key feature of the system was the Vicflex™ Style VS1 Dry Sprinkler, a product designed by Victaulic specifically for dry fire protection systems. Increasingly prominent due to its ideal application in clean rooms, the VS1 allows for a greater degree of movement, especially in the installation process. In fact, flexible drop sprinklers are also up to 10 times faster to install, increasing opportunities for monetary and time savings.

movement, especially in the installation process. In fact, flexible drop sprinklers are also up to 10 times faster to install, increasing opportunities for monetary and time savings.

The flexible drop sprinkler also helped overcome the significant issue of proper positioning. If a sprinkler head is not properly positioned within the ceiling plane, there is a chance it might not be exposed to heat and airflow. Subsequently, the ceiling acts as a heat deflector, potentially delaying or preventing the sprinkler from activating in time to check the growth of a fire.

Flexibility breeds capability

Complexity arose on this project given the added intricacy of designing and installing a piping system for an incredibly small space. Additionally, common in lots of industrial buildings, our customer’s manufacturing facility contained a false or two-level ceiling which essentially created a very tight gap where the piping could run.

Further to this, also contained within that tight space were a series of wires and piping for other trades and services. This resulted in what could be labelled as a ‘battle for space’ between different runs. As a late addition to the multitude of competitors, the fire protection piping had to work around what was already in place.

To tackle this challenge, the Vicflex™ Style VS1 Dry Sprinkler delivered again. Victaulic set about designing a blueprint which centred around flexibility, incorporating 80 of the flexible drops.

On this project, we knew installation was going to be difficult; the shear amount of competition for space alone meant the blueprints were more than likely not going to completely reflect reality and slight adjustments would be necessary. Without the use of the flexible drops, whole parts of the ceiling would have needed removal – an added nuisance which evidently would not have been appreciated by the client. The decision proved a success: by avoiding hard pipe connections and opting for flexible instead Victaulic could ensure all elements of the system were in their exact location.