Posted on September 3rd, 2024

Using dry sprinklers in wet systems is an effective solution for preventing freeze-ups, ice blocks, and bursts in areas exposed to freezing temperatures. However, installing the wrong barrel length can lead to catastrophic consequences.

Dry sprinklers can extend into unheated spaces without bringing the wet pipe system into areas prone to freezing temperatures. The problem is cold temperatures from unheated spaces will still travel into the heated space via the metal dry sprinkler pipe, which can lead to freezing when proper installation methods are not followed.

To prevent cold temperatures from the unheated space from freezing water at the sprinkler seal, a portion of the sprinkler pipe must be exposed to the heated space to allow it to warm up. For that, contractors need to determine the proper minimum exposed dry sprinkler barrel lengths required for the system.

What is the right dry sprinkler barrel length?

Before ordering dry sprinkler barrels, contractors should define the appropriate barrel length requirements for their system. When barrel lengths are too short, contractors may not have sufficient length at the installation point to meet the minimum dry barrel length requirements established in “NFPA 13: Standard for the Installation of Sprinkler Systems.” When barrel lengths are too long, the sprinkler’s K-factor starts to erode, and the sprinkler may not function as the system designer intends it to.

Maximum barrel length

Listing agencies will test hard barrel dry sprinklers up to an established maximum barrel length. While dry sprinklers are assigned a specific nominal K-factor, the actual K-factor of the sprinkler varies depending on the length of the dry barrel. As the dry barrel gets longer, water has more pipe to travel through, causing greater friction loss through the assembly and a slightly lower true K-factor. Listing agencies specify maximum dry barrel lengths to prevent too much variation in K-factors between shorter and longer dry barrels:

- The FM-approved maximum dry barrel length is 36”

- The UL-approved maximum dry barrel length is 48”

- The FM- and UL-approved maximum dry barrel length for flexible sprinklers is 58”

Many manufacturers offer longer barrel length options for hard pipe dry barrels. The authority having jurisdiction (AHJ) must approve use for longer barrels since they will not carry listings or approvals from the listing agency. In situations where the distance between the sprinkler and the wet system is too long, an alternate solution may be necessary, such as a dry, heat trace or antifreeze system.

Minimum barrel length

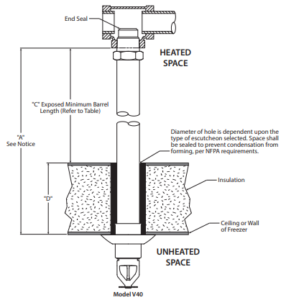

Determining minimum barrel lengths is a more intricate process. The barrel must be long enough to penetrate the barrier between the unheated space and the heated space. Additionally, it must extend into the heated space far enough that cold air from the unheated space doesn’t travel to the wet system. This portion of the pipe is called the minimum exposed length.

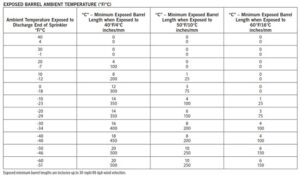

Per NFPA 13, “the minimum exposed length shall be measured along the length of the dry sprinkler from the face of the fitting to which the dry sprinkler is installed to the inside surface of the insulation, wall, or ceiling leading to the cold space, whichever is closest to the fitting.” Contractors should reference NFPA 13, 2022 Edition, Table 15.3.1 (a) or Table 15.3.1(b) when evaluating the appropriate minimum barrel length for their sprinkler system.

Key steps in determining minimum exposed dry barrel lengths

To use the NFPA 13 Table 15.3.1 (a) or Table 15.3.1(b) correctly, it’s important to first determine three key variables: exterior temperature, interior temperature and heated space envelope.

Exterior temperature

Sprinkler systems must be designed to withstand the lowest predictable environmental conditions. Contractors have an advantage with indoor sprinkler systems, such as in cold storage facilities, because building managers can control the internal temperature range. Meanwhile, sprinklers on the building exterior, such as balconies, are exposed to changing ambient temperatures with eacheasonal shift. Contractors must also consider how climate and average ambient temperatures will vary depending on the geographic region.

Contractors can use various tools to determine average extreme minimum temperatures to build safety factors into their decision-making process:

- USDA Plant Hardiness Zone Map — The USDA’s interactive map allows users to input their zip code to calculate historical winter temperature averages.

- Climate Data Online (CDO) — The National Oceanic and Atmospheric Administration’s global historical weather and climate database. Users can sort by local climatological and normal annual/seasonal data to determine average temperature extremes.

- National Weather Service — The National Weather Service offers forecast and seasonal outlook maps that contractors can use to assess an area’s climate patterns.

- ASHRAE Weather Data Center — The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) maintains a climatic conditions database with climate zone maps for 9,237 locations to support its members in making the best design decisions for building systems. The information is updated every four years.

- Plant Zones | landscape architect’s pages (wordpress.com) – While the above resources are specific to the United States, plant hardiness zone maps are also available for every region of the world.

Interior temperature

Part of the sprinkler barrel will need to be positioned inside the interior heated space. In a perfect world, the interior temperature will never approach freezing temperatures, but there’s no guaranteed way for contractors to control that. Therefore, they need to prepare for the worst-case scenario.

NFPA 13 Table 15.3.1 (a) and Table 15.3.1(b) outline minimum exposed barrel lengths when sprinklers are subject to 40°F, 50°F and 60°F temperatures. Unless the building owner or owner representative can write into their contracts that they will keep their building at 50°F, 60°F or higher, contractors should select 40°F as the interior temperature metric.

Some contractors will choose 50°F or 60°F to reduce material costs with shorter dry barrel lengths, but this decision adds significant risk. After all, they’ll have to answer to upset owners if pipes freeze and cause damage.

Heated space envelope

Contractors need to work closely with the engineer of record (EOR) and the AHJ to define the heated space envelope before making final decisions on dry barrel lengths. If the heated space begins at the edge of the exterior, insulation can lead to issues if the area in question is not directly connected to a heated space or if the insulation is not adequate to prevent cold air from getting in. The heated envelope should always be defined prior to choosing a dry sprinkler.

If there is any uncertainty about the building envelope, contractors should consider a conservative approach and opt for a more restrictive envelope. Exceeding the minimum barrel length requirements provides an additional safety factor and will not negatively affect the system performance. The only thing to be aware in this case is that the extra length could intrude on the occupant space.

The advantages of flexible dry sprinklers in freeze protection

Dry sprinklers enable designers to use wet systems — the most effective and cost-effective fire sprinkler systems — in unheated areas. Incorrect decisions regarding exposed barrel lengths can be a challenge in dry sprinkler scopes because they require analyzing multiple factors to ensure adequate freeze protection. Contractors must do their due diligence in meticulously evaluating the different variables that could detract from the systems’ effectiveness to deliver the best protection for occupants and property.

Flexible dry sprinklers like the Victaulic VicFlex™ Dry Sprinkler Series VS1 offer contractors an advantage when exterior protection is necessary. Hard pipe dry sprinklers must be installed in a straight line, meaning the sprinkler will have to penetrate back into the building at the height of the deflector on the building exterior. The portion of the dry sprinkler inside the building’s heated envelope must be at least the minimum barrel length designated by NFPA 13. Complying with these requirements can lead to unsightly piping or decorative soffits inside the building’s living or working space. In these instances, some contractors might take risks in their installation process to avoid the appearance of dry barrels in the occupied space.

Flexible dry sprinklers offer both flexibility and length that hard pipe dry sprinklers do not. Installers can maneuver the flexible sprinkler so that the minimum barrel length (or a longer section) is located within the building’s heated envelope without having to add soffits or exposed pipe. Flexible dry sprinklers are also offered in lengths of up to 58”, allowing installers to position the necessary portion in a heated space even if it’s farther away from the outside of the building. The flexibility and length of flexible dry sprinklers help keep the rest of the wet system away from the potentially cold exterior envelope of the building.

Victaulic offers education on identifying dry sprinklers, how they work, how they are installed, and how to identify the differences between both properly and improperly installed dry sprinklers. It can be found at the link below:

Dry Sprinklers for Commercial & Residential Fire Protection

1 Hour | 0.1 CEU | 1 PDH

https://victaulic.myabsorb.com/#/online-courses/54524102-f477-425e-baad-b39d7553880b

Connect with us to learn more

"*" indicates required fields