Kite Pharma

- Fabrication

- Training

- Virtual Design & Construction

- Carbon Steel

- Compressed Construction Schedule

- Cost and Schedule Certainty

- Ease of Installation

- Improved Safety

- On-site Training & Support

- Reliability

In 2020, biotechnology company Kite Pharma awarded the mechanical work for its new cell therapy manufacturing facility in Frederick, Maryland, to Warner Mechanical, Inc. The scope of work involved installing a reliable cooling and heating system in the 279,000-square-foot facility where Kite Pharma would produce innovative cell therapy treatments for cancer patients. The complex system included three cooling towers, three chillers, four boilers, ten pumps, and 68,000 linear feet of 24-inch diameter and down mechanical piping.

The large-scale project’s construction schedule was tight, so Warner Mechanical partnered with Victaulic to expedite installation and meet the owner’s deadline. The task became even more challenging two months into the project when COVID-19 spread across the U.S. and Warner Mechanical hurried to establish and implement new health guidance for employees. The pandemic affected both the availability of skilled labor and the number of workers who could be on a job site at a time.

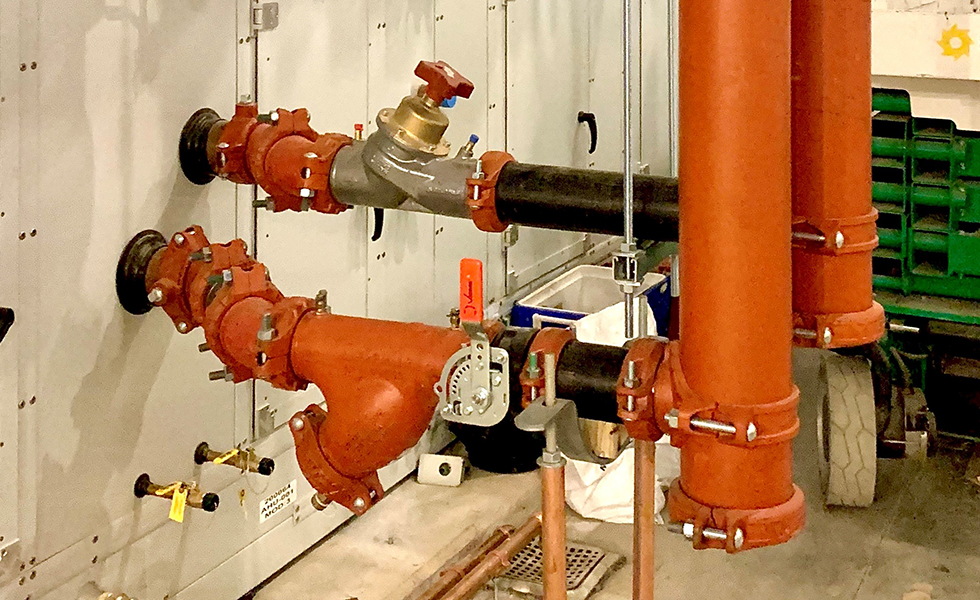

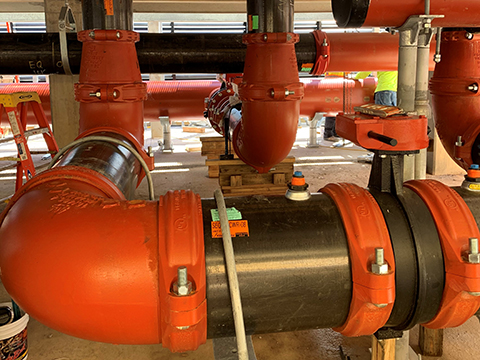

Victaulic Virtual Design & Construction (VDC) used a 3D Revit model of the mechanical space to design pipe schematics and identify potential job site challenges before installation began, which helped mitigate delays. Once drawings were approved, the VDC team sent spooling details to the fabrication shop, and tagged pipe spools arrived onsite. Warner Mechanical significantly improved schedule certainty upfront by leveraging the VDC team and a prefabrication strategy. Installing modular products — including pump drops, air handling unit drops, and Series 799 KOIL-KIT™ packs — helped reduce the number of overall joints by 70%.

Additionally, Victaulic representatives trained workers in a single day to use rolled grooving equipment and install Victaulic QuickVic™Style 107V Rigid Couplings, fittings, and butterfly valves. The grooved pipe-joining technology is designed for ease of installation using an impact gun to join two components. In addition to streamlining installation, utilizing QuickVic™ decreased the number of pipefitters required for the job and mitigated worker safety risks by eliminating welding, wrenching, and torquing. With significant labor savings realized, Warner Mechanical was able to bid and begin work on additional jobs in 2021.

Warner Mechanical’s collaborative business partnership with Victaulic led to an efficient and successful mechanical system installation at Kite Pharma’s state-of-the-art facility. The full mechanical installation was completed ahead of schedule. This allowed Kite Pharma to earn FDA approval six months ahead of schedule and begin producing life-saving cancer therapy treatments sooner than initially anticipated.