Last Updated on May 21, 2018

Originally Posted on January 12, 2016

We sat down with Ralph Schoch, Revit, Technology and Internal Support Manager, to tap his grooved pipe joining expertise on how using Revit can change the way engineers design grooved piping systems and improve their projects.

Victaulic: What can customers and Revit users do with the expertise you provide through your Virtual Construction and Design (VDC) team?

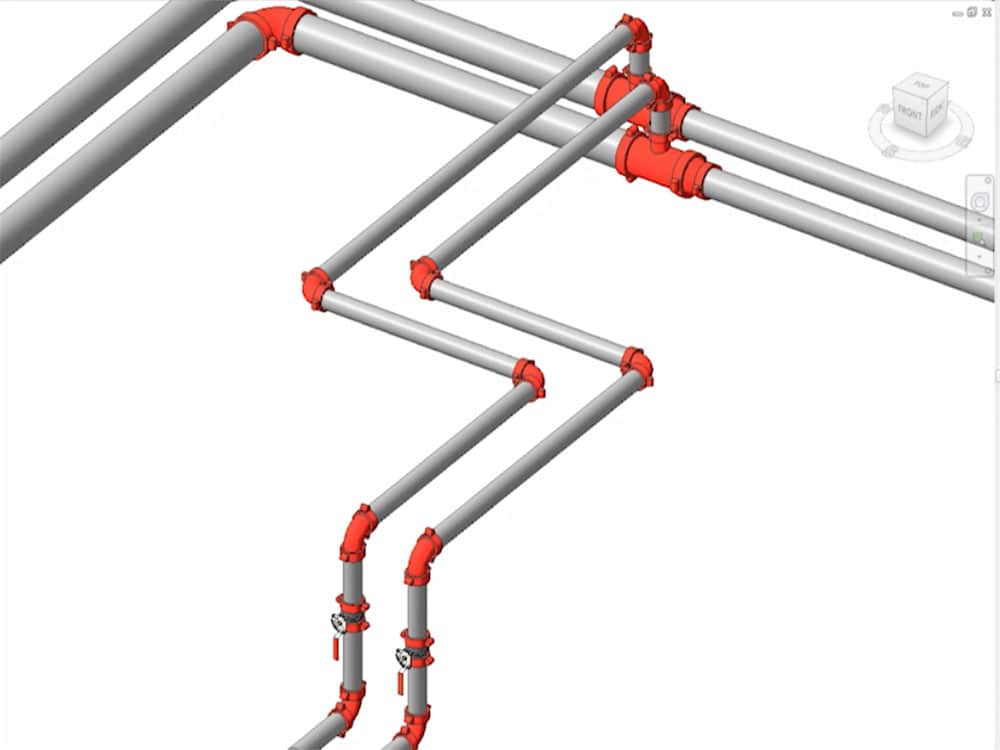

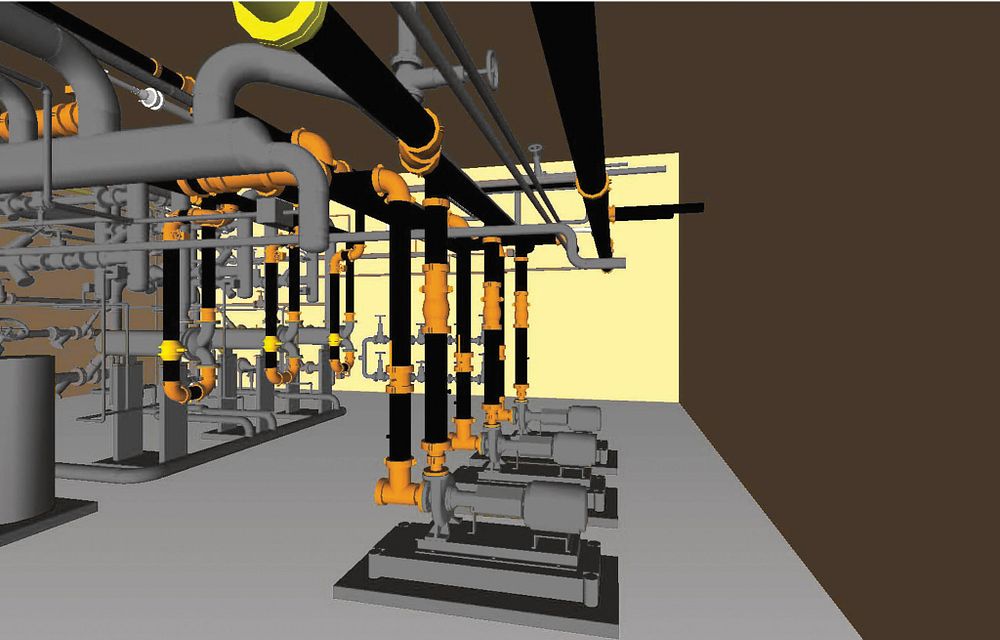

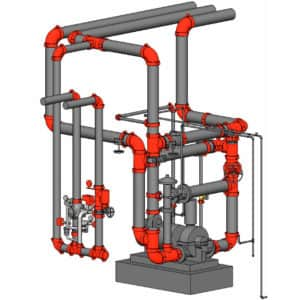

Ralph Schoch: When a customer comes to Victaulic for help designing systems, we provide the tools through our Revit families for them to efficiently create complex pipe routing systems. The families, which are native within Revit, help define piping types to automatically place when routing the piping.

Our “Victaulic Tools For Revit” add-ins allow us to improve user efficiency throughout the routing and bill-of-material process. Once the routing is complete we can then help create fabrication assembly documents of the piping system. We also provide BIM services for estimation and model creation.

RS: A software add-in is a type of program module (or file) that adds functionality to a software product, usually in the form of a command automating a task or some customization of the product’s behavior. When you talk about an add-in for Revit we mean a module containing code that makes use of the Revit API (Application Program Interface). Revit loads such add-ins and uses them to adjust its behavior when the user of the add-in executes a particular command.

Vic: What makes the “Victaulic Tools For Revit” valuable?

RS: Without these Victaulic tools the methods for creating construction documentation are slow and difficult to manage. Using the tools drives increased productivity by automating the bill of material creation, sorting, and exporting process when creating construction documentation in Revit. The tools automate the tagging, sequencing, and drawing tag placement for pipes and components, along with the order, selection, and creation of assemblies within the project. If engineers aren’t using them and instead have the “generic” families, those may not be optimized for routing and documentation, which increases the work required to create it.

Vic: How much time can this save during the course of a project?

RS: With the combination of Victaulic’s switch to Revit and our customized tools we have seen in-house productivity of up to 20 percent over Autodesk Fabrication CADmep software deliverables.

Vic: What will someone notice when they switch from traditional 2D AutoCAD software to Revit?

RS: Revit is an opportunity for traditional AutoCAD users to do their work in a new way, review their current work processes, and develop a new set of deliverables. At the outset it can seem as if a new user has to re-learn how to create projects based on what Revit wants, and it can seem daunting. Taking the time to set up your content and properly set up project templates can shorten the initial learning curve tremendously. Victaulic’s product family library is helpful to new Revit users as they optimize that set-up.

Eventually as new users gain comfort with the program they will start to understand how the software works and the benefits become evident. It’s not uncommon for a user to learn Revit and not go back to AutoCAD at all, that’s how powerful and beneficial the software can be.

Vic: What goes into creating Revit content from Victaulic that benefits a customer’s project?

RS: The methods used to create Revit families can greatly affect the final deliverables within the project. When creating content, we test each family to make sure it functions correctly in the project routing. We also test the content in all levels of detail to assure what we present provides the correct representation in all display levels.

We develop our native content, but more importantly we also use and test our content on projects with our in-house BIM Services Team. This gives us the knowledge to be able to understand and solve any content-related issues our customers may have.

Vic: What considerations go into developing Revit families?

RS: We pay careful attention to how the parameters are written, the number of types and the way in which the family routes in a system to be sure they display properly throughout the various levels of detail. We also place emphasis on how subcategories can be used to control visibility. We take file size into consideration, specifically looking for ways to keep the size to a minimum.

Vic: In regard to file size, can you address concerns about how including custom families would affect file size and performance?

RS: The common myth is that the size of a family can affect the project’s performance the more it is used. We tested this by loading our Victaulic elbow family into a fire protection piping project designed for a 20-story building. After switching all the elbows throughout the project to the Victaulic elbow the total file size increased by only 308kb – the size of one family.

We then tested model performance and no change was evident. This tells us that we can improve the quality of our project by including the necessary Victaulic families and not always pay a price on performance or file size.

One other point we have discovered is that it isn’t always the size of the family but the way parameters are written and how the family is designed to flex that can affect project routing performance the most. That’s where developing our families plays an important role. We build them knowing the best way to write and design them.

Vic: Why is more detail, such as using Victaulic elbows instead of generic Revit renderings, helpful in a Revit drawing?

RS: By adding higher levels of detail in the correct areas of your project you can help reduce RFIs that slow down the project later on. More detail helps you improve calculations and assist in the project quoting process. All of this additional data in the model can also be passed to the owner for aid in facilities management.

Vic: Is Revit support affected by different markets or pipe materials?

RS: Right now we support all major markets that use Revit for design. We have built out Revit families to support Victaulic products in aluminum, carbon steel, copper, stainless steel, and AWWA-standard materials.

Vic: Beyond Revit, what other software systems does the VDC support?

RS: We support more than 20 major software platforms that our customers work with, including many Autodesk, Intergraph, and Bentley solutions.

Vic: How does Victaulic work with VDC customers to make sure their Revit content imports and routes go smoothly?

RS: When a customer has an issue we work one on one to resolve it. If this means email, phone call, or even connecting remotely to their computer, we will do what it takes to resolve the issue for our customer.

Vic: After more than five years working to implement Revit designs, in what ways have interacting with customers helped improve the Revit services the VDC provides?

RS: We value the input from customers on our content and services. Currently, we have received many comments from the engineering community, and we are listening. We will be providing engineering specific content with an emphasis on usability and display representation all within a template that you can transfer pipe types that are predefined and ready to go. This new content will be a mix between generic and manufacturer specific. We are also working on various customer training events with more details to follow.

We appreciate Ralph taking the time to address the common questions people have when considering Revit for their piping system design.

Vic: Where do I go to get Victaulic Tools for Revit add-on?

RS: You can download a 30-day free trial or purchase Victaulic Tools for Revit (VTFR) by visiting VictaulicSoftware.com