Indeck Niles Power Station

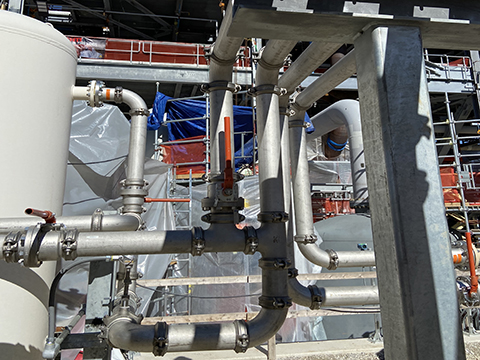

- Carbon Steel

- Stainless Steel

The Indeck Niles Energy Center was built to generate 1,000 megawatts of energy through the use of clean natural gas and state-of-the-art technologies, replacing older and less efficient coal-fired power plants. With the ability to produce enough energy to power 635,000 homes and businesses, the Indeck Niles Energy Center will be the most efficient power plant in the state of Michigan.

On this new combined-cycle power plant, Victaulic’s solutions for the power market were installed throughout the potable water system, instrument air system, service water system, denim water system/treatment, and fire water system.

Kiewit selected Victaulic to be their total piping solution partner and provide more than just couplings, fittings, and valves. During the pre-construction, Victaulic’s Virtual Design and Construction (VDC) Team supported Kiewit’s design team by providing grooved piping solutions that delivered inherent value engineering to the project. Victaulic’s spool drawings helped improve the build strategy to reduce field installation and material handling on the jobsite. The timing of the Victaulic spools to the Indeck Niles jobsite mated precisely to Kiewit’s build strategy and delivery date. These upfront efforts saved Kiewit construction man-hours in the field and mitigated the risk of cost overages due to incorrect material orders and rework.

During the construction, Victaulic Fabrication helped Kiewit exceed its project goals by implementing LEAN principles, optimizing the number of truckloads, and delivering fabricated spools according to Kiewit’s build strategy. Quality controlled pipe spools arrived clearly marked, coordinated with the spool map exactly, and fit together like an erector set. This allowed for a quick and efficient installation by the construction crew, no matter which shift was chosen.

External Link