Posted on November 15, 2018

3 Reasons Victaulic® Chose BERMAD Control

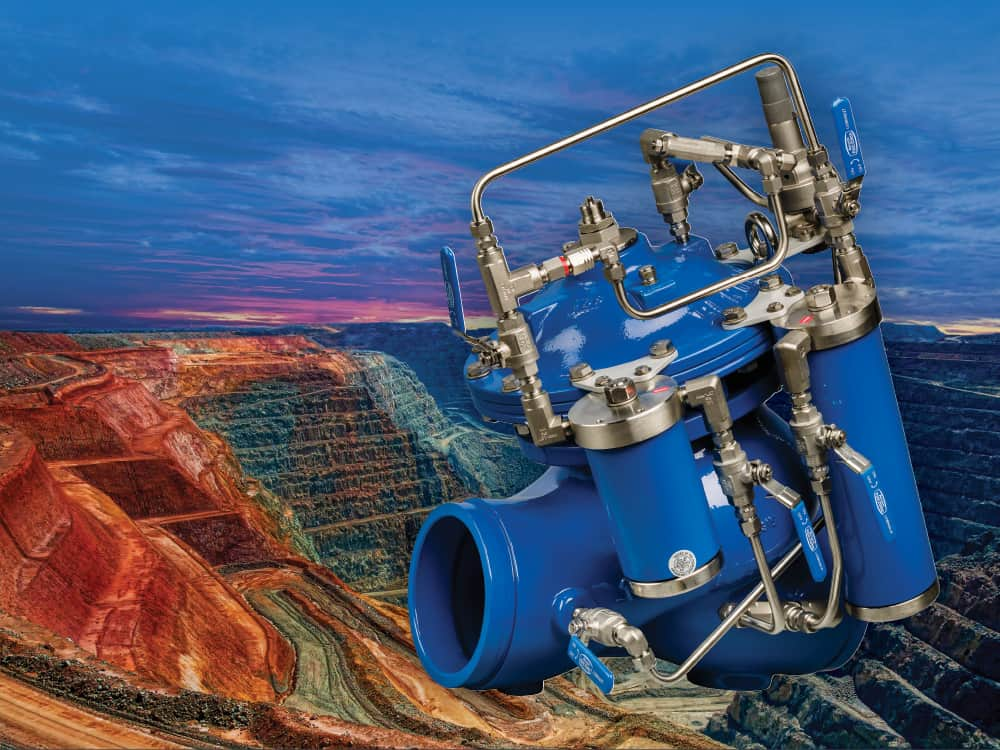

The combination of Victaulic grooved ends on BERMAD hydraulic control valves creates the best control valve solution available.

1. Double-Chambered, Modular Actuator.

Maintaining a BERMAD valve is up to 8 times faster, as moving parts are contained within one module. Merely remove the actuator assembly for quick cleaning or replacement.

2. “Y” Pattern Valve.

Up to 15% better flow capacity than standard globe valves, due to the direct, y-pattern flow path and obstruction-free design.

3. Center Guided Plug.

Single point guidance maintains actuator alignment without obstructing flow path, providing a durable and robust solution. Adding an optional v-port throttling plug provides added flow stability in low flow conditions.

BERMAD hydraulic control valves can be configured to provide on/off, pressure reducing, pressure sustaining, pressure relief, surge anticipating, level control, or pump control service for industries including fire protection, waterworks, mining, and more. BERMAD valves with grooved connections are also suitable for use in high pressure applications, such as in high rise buildings or ultra-deep mines.

Why Did BERMAD Choose Victaulic®?

1. No Welding Required

In the face of today’s shortage of skilled welders, this is a welcome feature for many contractors and project managers. As flanged ends must be welded to the pipe spool, mechanical-joining can remove project delays due to welder availability and reduce labor costs for a project.

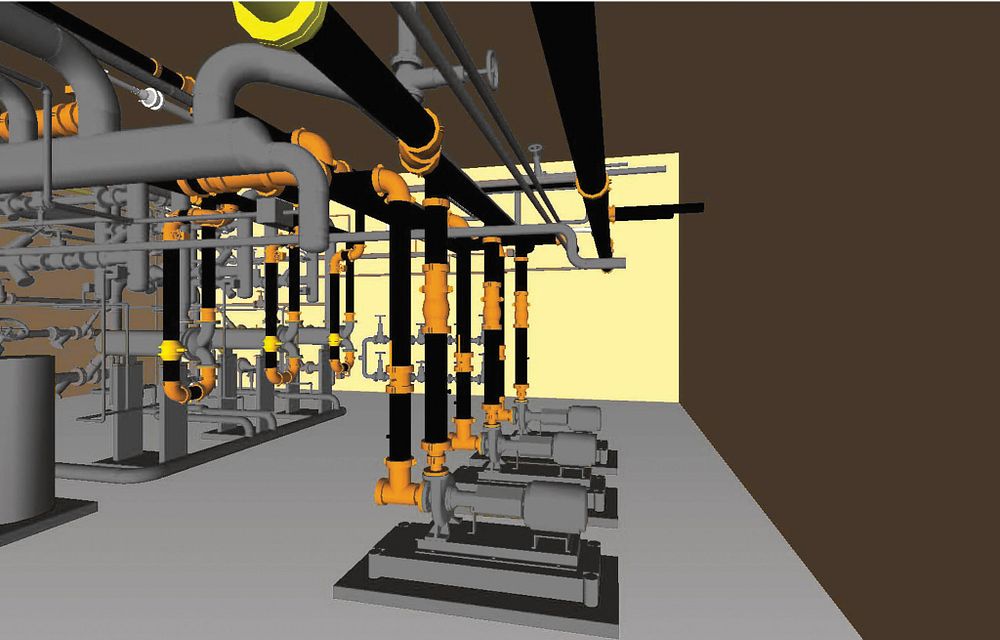

2. Victaulic® Grooved Ends Save Time and Enhance Durability

Victaulic systems are installed quickly and alleviate stress in piping systems caused by numerous environmental factors, such as seismic and thermal movement and noise and vibration attenuation.

For more information about the benefits of using BERMAD valves with built-in Victaulic grooved ends for your next project, contact us here and connect with a Victaulic representative in your region.